PORTLAND — After they’ve been washed, washed again, sauced, cooked, sauced again, canned and sealed, B&M Baked Beans are dropped into massive pressure cookers with massive lids held on tight by six nuts that are each half the size of a grown man’s arm.

Steam rushed off those countless lids in tidal waves during a tour on a recent morning.

I’m in awe and wilting. Awe, wilting.

And it doesn’t seem to bother Dave Rickett a bit.

He’s walked B&M’s five floors for 44 years. His dad did it for 46.

As the company celebrates 150 years, B&M has been inviting media in for a peek behind the beans. Rickett, production supervisor, was a natural pick for our tour guide.

“I have one gentleman who works for me who’s going for his 50th (year), and this is not his first job,” said Rickett, walking from the lobby into the 225,000-square-foot plant.

That gentleman originally worked at Homemaker Company, another Portland bean maker that B&M bought almost 50 years ago.

“He came with the package, I guess,” said Rickett.

All around us, the air is sweet with molasses. We’re in lab coats and hair nets, rings off, ready to bean it up.

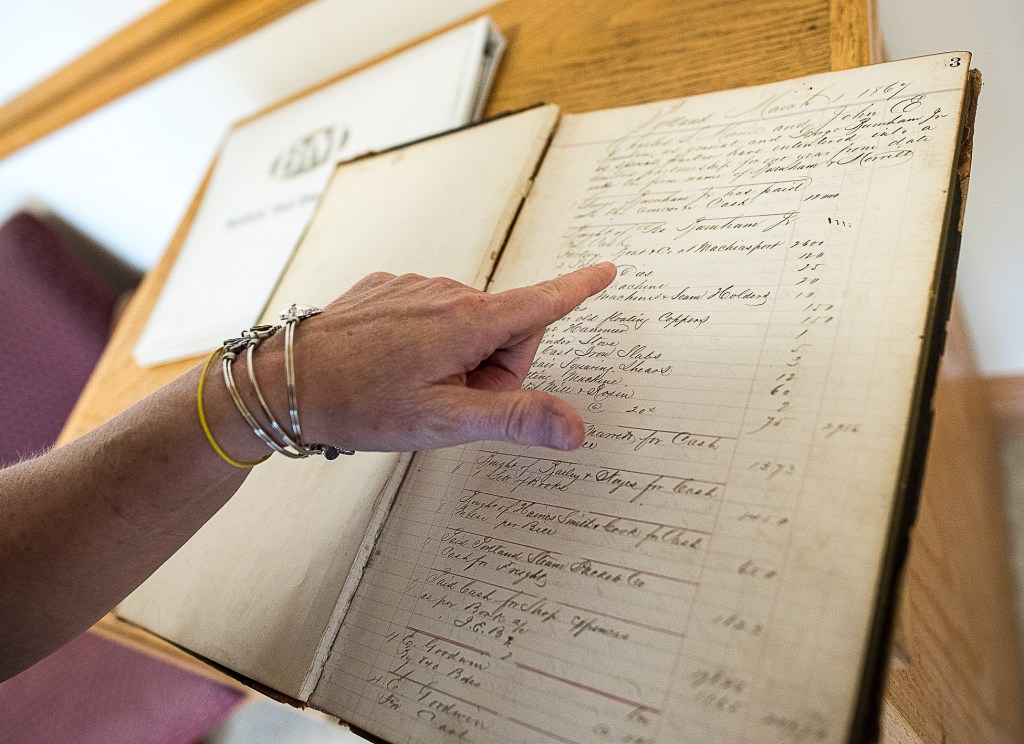

The B&M factory, with its iconic 150-foot smokestack visible from I-95, has enjoyed a long, colorful history. The company started in March 1867 with the partnership of canners George Burnham and Charles Morrill, first in an Old Port facility. They canned roast beef, mutton, lobster, clams, turnips and carrots, to name a few, according to a company handout.

By 1913, when they built the current factory, Fish Flakes, used in chowders, were a staple. In the 1920s, B&M added baked beans. Both hit a snag in World War II: “Fish Flake and Baked Bean lines run into production obstacles as the U.S. government imposes restrictions on can sizes for Fish Flakes, implements price controls and seizes fishing fleets for conversion to mine sweepers,” the handout states.

Fish Flakes’ days are over. Beans endure.

Flash forward and the factory today makes 15.5 million cans of baked beans a year, the only bean factory in B&M’s arsenal. B&M beans are sold mostly in New England and Canada, according to Kelly Rickett, B&M’s human resource supervisor and Dave’s wife. (They met at work. Aww.)

Present-day corporate parent B&G Foods bought Green Giant more than a year ago and B&M recently started making its beans for the Midwest market, she said.

The Portland factory also cans Ortega refried beans and Underwood meat spreads, but the rock stars at 1 Bean Pot Circle are clearly the beans.

MIXING IT UP

With the exception of very modern touches like a vending machine that metes out gloves, bandages and knives with the swipe of an ID badge, the inside of the plant reads very timeless industrial.

Rickett said not much has changed about the process of making baked beans for the past 100 years except for automation improvements. The dry navy beans arrive in 2,000-pound “super sacks” on the first floor. It used to be someone’s job to slice bean bags open all day; now, machines do it.

Beans are piped in batches from the first floor up to the fifth, where they’re washed and blanched at 190 degrees for several minutes.

“It adds moisture to the bean,” Rickett said.

From there, the beans are channeled down to the fourth floor where the magic happens. Beans are portioned into giant 200-pound pots. They hit the sauce station where water, mustard and other ingredients are added — think lots of buttons, determining each batch’s favor — and are then hand stirred by one of 100 employees.

“I’m not sure they could automate it and actually have it come out the way they want,” Rickett said.

Pots are then navigated into brick-lined gas ovens through a hook and overhead rail system, where they bake for several hours.

With all that baking, water and saucing, according to Rickett, 388 pounds of wet fifth-floor beans becomes 900 pounds of consumer-ready side dish.

Rickett’s favorite B&M flavor is bacon and onion. Just so happens, it’s a bacon and onion day.

BEANS WITH A VIEW

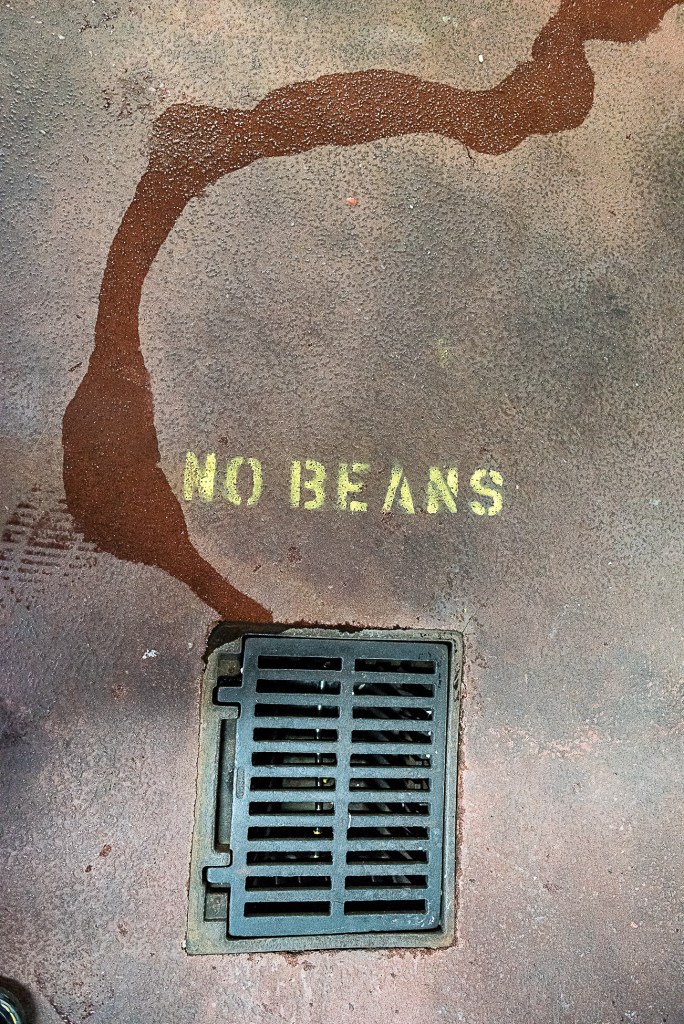

The finished beans are gravity-fed down to the third floor for packaging and a long bout in the super-steamy pressure cookers, between 90 minutes and five hours, depending on the flavor. That last step prevents bacteria from getting into the can, Rickett said.

From there, cans are given time to cool. They’re labeled and organized on a conveyor belt and sent down to the warehouse. (Picture something like the last scene from “Raiders of the Lost Ark,” but beans.)

“Look at that view,” Rickett said at one point during the tour, pausing to look out over Casco Bay through enormous windows. “I think we take it for granted coming to work every day.”

The factory’s real estate is valuable, assessed by the city at $6.1 million for the land and building.

“At one time, somebody wanted this piece of property for condos,” he said.

As he heard it, B&M said sure, you can have it for X dollars. The would-be condo developer didn’t bite.

Rickett, who lives in Saco, said his father wasn’t the reason he originally wanted a job at the baked bean factory at age 19, but it made getting in easier.

“This was steady (work) and I’m still here,” he said.

And after 150 years, so is B&M.

Send questions/comments to the editors.